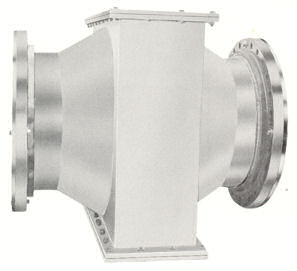

Type E-21 Flame Arrestors

Flame Arrestors – Cast Body

Flow Charts

AutoCAD

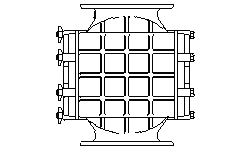

- 2″ E21, Front View

- 3″ E21, Front View

- 4″ E21, Front View

- 6″ E21, Front View

- 8″ E21, Front View

- 10″ E21, Front View

- 12″ E21, Front View

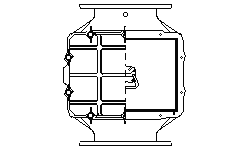

- 2″ E21, Right Side View

- 3″ E21, Right Side View

- 4″ E21, Right Side View

- 6″ E21, Right Side View

- 8″ E21, Right Side View

- 10″ E21, Right Side View

- 12″ E21, Right Side View

Specifications

| SIZES: | 2, 3, 4, 6, 8, 10 and 12 inch |

|---|---|

| BODY: | Cast Iron, Aluminum, Cast Steel, 304 Stainless Steel, 316 Stainless Steel |

| COVERS: | Cast Iron, Aluminum, Cast Steel, 304 Stainless Steel, 316 Stainless Steel |

| ELEMENT: | Aluminum or Stainless Steel |

| CONNECTION | |

| 2 and 3 inch | N.P.T. |

| 2, 3, 4, 6, 8, 10 and 12 inch | 125 lb. ANSI Std. |

Dimensions

| OVERALL DIMENSIONS IN INCHES | SHIPPING WT. LBS. | ||||

|---|---|---|---|---|---|

| Size | Side to Side | Front to Back | Face to Face | Aluminum Element | Stainless Steel Element |

| 2 | 7 3/4 | 8 1/4 | 8 | 40 | 50 |

| 3 | 9 | 9 1/4 | 11 | 75 | 100 |

| 4 | 12 1/2 | 11 5/8 | 13 1/4 | 115 | 145 |

| 6 | 13 3/4 | 14 1/8 | 18 | 200 | 265 |

| 8 | 16 7/8 | 17 1/2 | 21 1/4 | 340 | 515 |

| 10 | 21 5/16 | 24 1/2 | 24 1/2 | 705 | 1025 |

| 12 | 21 5/16 | 29 13/16 | 29 | 910 | 1335 |

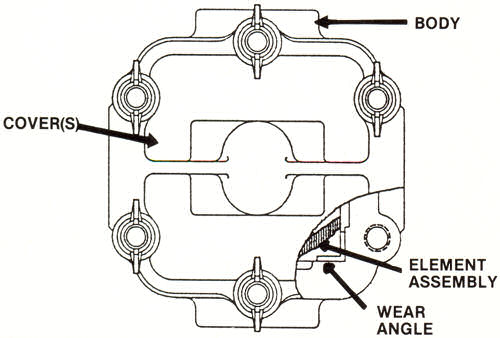

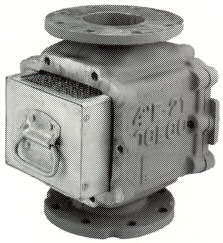

OCECO Type E-21 Flame Arrestors have won world-wide acceptance in the petroleum and chemical industries as the result of an unsurpassed record of safety, performance, and durability. OCECO flame arrestors prevent the propagation of flames by absorbing and dissipating heat. Ignited vapors attempting to pass through the element assembly are broken into small streams by passages formed in the element sheets.

The absorbed heat reduces the temperature of the individual flame fronts below the auto ignition temperature of the vapor mixture and the flame is "quenched". The vapor mixture will continue to burn on the downstream end of the bank until the source of the flammable mixture is eliminated or the flame is snuffed out.

OCECO flame arrestors are designed for use on volatile liquid storage tank, where vapors expelled during thermal expansion or filling operations may become ignited. They have also been successfully applied in certain non-standard applications to prevent "flashback" fires in process piping.

The standard unit consists of a cast iron housing and either an aluminum or stainless steel element assembly. The element is easily removed from the housing for routine maintenance and inspection. It is strongly recommended the factory be consulted for non-standard applications on variations from the purpose for which this equipment was engineered.

Special materials, steam jacketing, horizontal installation, and protective coatings are available on request.