Type V-108 Emergency Vents

Emergency Pressure Relief Vent Valve

Flow Charts

Specifications

| Specifications | ||

|---|---|---|

| Sizes: | 6, 8 and 10 inches | |

| Body: | Carbon Steel | |

| Valve Top: | Aluminum or Cast Iron | |

| Seat Ring: | Aluminum or Stainless steel | |

| Insert: | Buna-N or Teflon | |

| Flange: | 125 lb. ANSI Standard | |

| Settings: | ||

| Minimum | Maximum | |

| Aluminum Valve: | 3″ WC | 1 PSI |

| Cast Semi-Steel Valve: | 7″ WC | 1 PSI |

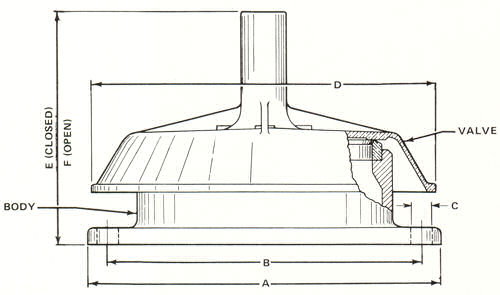

Dimensions in Inches

| Valve Size | A | B | C | D | E | F | Gross Wt. (lbs.) |

|---|---|---|---|---|---|---|---|

| 6″ | 11 | 9 1/2 | 3/4-8 | 8 1/8 | 8 1/16 | 9 11/16 | 30 |

| 8″ | 13 1/2 | 11 3/4 | 3/4-8 | 13 3/8 | 9 7/8 | 12 3/8 | 60 |

| 10″ | 16 | 14 1/4 | 7/8-12 | 15 13/16 | 10 7/8 | 13 7/8 | 65 |

OCECO Type V-108 Emergency Pressure Relief Vent Valves are designed to provide additional venting capacity beyond that of the working vent to relieve excessive internal pressure resulting from unusual conditions. Several examples of this condition may include: exposure to fire, chemical reaction or failure of the breather vent to operate.

The protection provided by emergency vents is often required by municipal "Flammable Liquids Codes" to prevent the possibility of tank rupture and subsequent loss of product.

OCECO Type V-108 Vent Valves are corrosion resistant in petroleum as well as hydrocarbon storage applications. They are stem guided with self closing covers that reseat themselves automatically after tank pressures have been relieved. As these vents do not remain open longer than necessary, costly evaporation losses are prevented.

Special, spring loaded V-108's are available for higher relief settings.