Type V-130 Vent Valves

Documents

Flow Charts

Download Drawings

Specifications

SIZES: 2, 3, 4, 6, 8, 10 and 12 inch

BODY: cast aluminum

VALVES: cast aluminum

HOOD: spun aluminum

Membranes and settings

| Minimum | Maximum | |

|---|---|---|

| Polyblend | 1/2 oz | 16 oz. |

| Viton | 1/2 oz. | 16 oz. |

| Teflon | 1/2 oz. | 16 oz. |

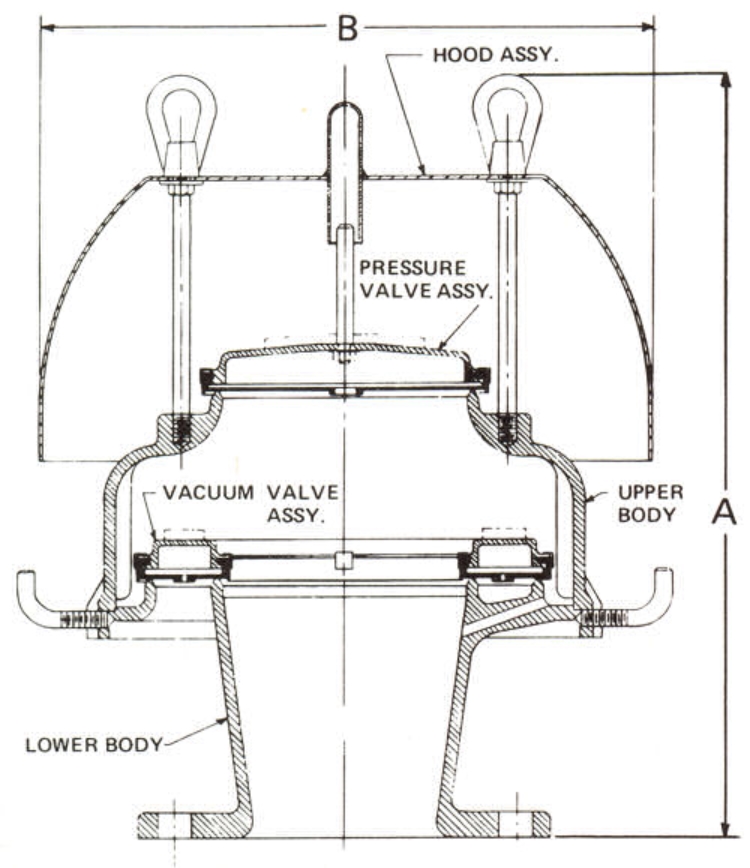

Table of Dimesions and Weights

| SIZE | DIMENSIONS IN INCHES | Effective Area of Valves (Sq. inch) | Approximate Weight Lbs. | |||

|---|---|---|---|---|---|---|

| A | B | Pressure | Vacuum | Net | Shipping | |

| 2″ | 17 5/8 | 14 1/2 | 24.253 | 30.306 | 19 | 32 |

| 3″ | 17 5/8 | 14 1/2 | 24.253 | 30.306 | 19 | 32 |

| 4″ | 17 5/8 | 14 1/2 | 24.253 | 30.306 | 19 | 32 |

| 6″ | 24 | 19 7/8 | 54.70 | 69.30 | 50 | 80 |

| 8″ | 28 5/16 | 26 3/8 | 84.50 | 107.20 | 70 | 110 |

| 10″ | 32 1/4 | 31 1/2 | 142.50 | 177.25 | 100 | 130 |

| 12″ | 35 3/4 | 31 1/2 | 209.80 | 250.80 | 130 | 200 |

With any type of closed liquid storage vessel, the importance of adequate venting capacity cannot be over-emphasized. Serious structural damage will result to a tank if maximum design pressures are exceeded.

Conservation vent valves were designed to permit atmospheric steel storage tanks to "breath" and to minimize the loss of valuable vapors during periods of pressure and relief.

Since their inception, conservation vent valves have undergone major design and flow capacity improvements.

The OCECO type V-130 conservation regulator is the finest "conventional" vent available. It is constructed primarily of aluminum and is, consequently, ideal for petroleum or hydrocarbon storage applications. This unit provides excellent flow, even at low tank pressure, as shown on the flow chart.

The flexible synthetic membrane, in addition to providing a positive seal, makes the V-130 virtually non-freezing even under severe climatic conditions. A variety of membranes are available to meet most corrosive applications.